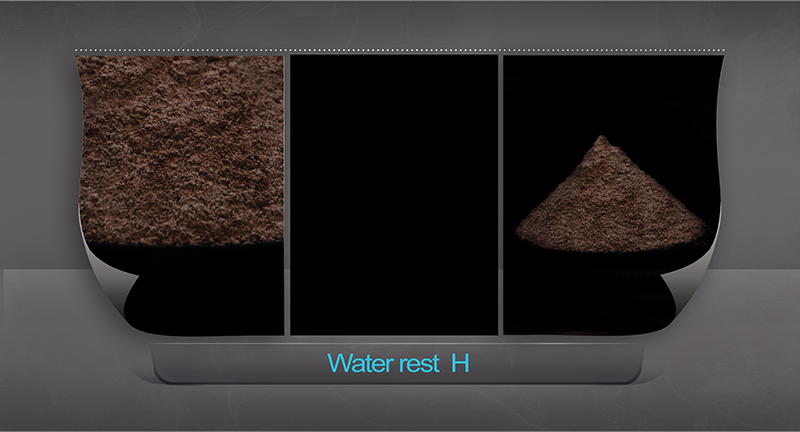

Water rest H

Water proof polymer cements (H)

This product is made based on strengthened cement by strong chemical polymers which are highly resistant against water. They are made based on the cutting-edge technology of polymeric cement and are presented in various colors that give special beauty to the surface.

This is a mortar is made up of particular additives to prevent water penetration. This product will be hard after getting dried and won’t be reflexive. It can be implanted with those beddings that are always in contact with water.

Advantages

· Steam impermeable

· Have a high adhesive

· Have a stable flexibility.

Dosage

The approximate dosage for each square meter is 1-1.5 kilograms which should be rubbed with a brush. The obtained paste must be rubbed on the surface using a trowel.

Preparing the foundation surface

First wash the surface with water to remove the dust completely. When the surface is completely waterlogged, there is sufficient moisture to avoid the water absorption by beneath surface.

If there is a crack or gap on the surface, first wash it with water and then fill it with the repairing paste to overlap with the final surface.

Start your work from top to bottom.

The completion process should be done in two stages. The interval between two stages should be 30 minutes. If the implementation of the second stage is delayed for more than 15 hours, the beneath surface must be sprayed with water.

How to make the paste and implantation points

For each liter of water, add 1.25 kilograms of the powder gently and mix them with the mechanical mixer; continue the mixing process for 2 or 3 minutes to obtain a homogeneous paste. Then, wait for 5 minutes so that the polymers inside the paste start reacting chemically with the cement. Then, mix the paste again and rub it with a brush on the surface.

The prepared paste must be used in 45 minutes or at most 1 hour.

The underlying surface must be finished appropriately or be softened. The smoother the surface is, less water rest will be used.

Specifications

Appearance: color powder

Approximate efficiency: 1kg/m2

Heating & cooling resistance: between -15 to + 70 degrees of centigrade

Appropriate implantation thickness: between 1 to 3 mm

Packaging and maintenance

keep in four-ply 25-kg pockets with plastic cover.

Safety points

This powder contains no toxic materials. To avoid inhaling cement materials, use cloth mask.